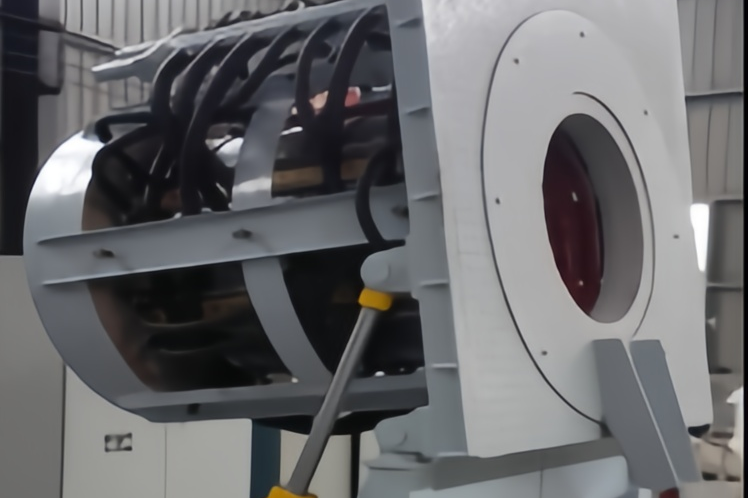

Cylindrical crucible ejiri mee ọkụ induction na ọkụ gas

NDỤMỌDỤ NKE EKPERE

Nrụpụta okpomọkụ dị elu

Ngwakọta pụrụ iche nke silicon carbide na graphite na-eme ka ikpo ọkụ dị ngwa na otu, na-ebelata oge ịgbaze.

Nguzogide oke okpomọkụ

Ngwakọta pụrụ iche nke silicon carbide na graphite na-eme ka ikpo ọkụ dị ngwa na otu, na-ebelata oge ịgbaze.

Nguzogide nrụrụ na-adịgide adịgide

Ngwakọta pụrụ iche nke silicon carbide na graphite na-eme ka ikpo ọkụ dị ngwa na otu, na-ebelata oge ịgbaze.

Nkọwapụta nka nka

| Graphite /% | 41.49 |

| SiC / % | 45.16 |

| B/C / % | 4.85 |

| Al₂O₃ /% | 8.50 |

| Nnukwu njupụta / g·cm⁻³ | 2.20 |

| Nke pụtara porosity /% | 10.8 |

| Ike ihichapu / MPa (25 ℃) | 28.4 |

| Modul nke mgbawa/MPa (25 ℃) | 9.5 |

| Ọkụ na-eguzogide okpomọkụ / ℃ | >1680 |

| Thermal ujo eguzogide / Times | 100 |

| Ụdị/Ụdị | A (mm) | B (mm) | C (mm) | D (mm) | E x F kacha (mm) | G x H (mm) |

|---|---|---|---|---|---|---|

| A | 650 | 255 | 200 | 200 | 200x255 | Mgbe a rịọrọ ya |

| A | 1050 | 440 | 360 | 170 | 380x440 | Mgbe a rịọrọ ya |

| B | 1050 | 440 | 360 | 220 | 380 | Mgbe a rịọrọ ya |

| B | 1050 | 440 | 360 | 245 | 440 | Mgbe a rịọrọ ya |

| A | 1500 | 520 | 430 | 240 | 400x520 | Mgbe a rịọrọ ya |

| B | 1500 | 520 | 430 | 240 | 400 | Mgbe a rịọrọ ya |

Usoro erugharị

1. Nhazi nkenke

Grafite dị oke ọcha + silicon carbide adịchaghị + onye na-ejikọ ọnụ.

.

2.Isostatic Pressing

Njupụta ruru 2.2g/cm³ | Nlegide ọkpụrụkpụ mgbidi ± 0.3m

.

3.High-Temperature Sintering

SiC urughuru recrystallization na-akpụ nhazi netwọkụ 3D

.

4. Nkwalite elu

Mkpuchi mgbochi ọxịdashọn → 3 × mma nguzogide corrosion

.

5.Nnyocha Ogo siri ike

Koodu nsochi pụrụ iche maka traceability okirikiri ndụ zuru oke

.

6.Nkwakọ ngwaahịa nchekwa

oyi akwa na-awụ akpata oyi n'ahụ + ihe mgbochi mmiri + mkpuchi mkpuchi siri ike

.

Ngwa ngwaahịa

Igwe ọkụ na-agbaze gas

Ọkụ na-agbaze Induction

Igwe ọkụ na-agbaze na-eguzogide

GỊNỊ mere ahọpụtara anyị

FAQS

Q1: Gịnị bụ uru nke silicon carbide graphite crucibles tụnyere omenala graphite crucibles?

✅Nguzogide okpomọkụ dị elu: Nwere ike iguzogide 1800 ° C ogologo oge na 2200 ° C obere oge (vs. ≤1600 ° C maka graphite).

✅Ogologo ndụ ogologo: 5x ka mma thermal ujo eguzogide, 3-5x ogologo ndụ ọrụ ogologo.

✅Mmetọ efu: Enweghị ntinye carbon, na-ahụ na ọ dị ọcha ọla a wụrụ awụ.

Q2: Kedu ọla nwere ike ịgbaze na crucibles ndị a?

▸Ọla nkịtị: Aluminom, ọla kọpa, zinc, gold, silver, wdg.

▸Ọla na-emeghachi omume: Lithium, sodium, calcium (chọrọ mkpuchi Si₃N₄).

▸Ọla Refractory: Tungsten, molybdenum, titanium (chọrọ ikuku / inert gas).

Q3: Ọhụrụ crucibles chọrọ tupu ọgwụgwọ tupu eji?

Achịcha mmanyere iwu: Jiri nwayọọ na-ekpo ọkụ ruo 300 ° C → jide maka awa 2 (na-ewepụ mmiri fọdụrụnụ).

Nkwanye mgbaze mbụ: Buru ụzọ gbazee otu ihe mkpofu (na-etolite akwa mkpuchi).

Q4: Olee otú iji gbochie crucible cracking?

Ejila ihe oyi na-atụ n'ime ọkụ ọkụ (max ΔT <400°C).

Ọnụego jụrụ oyi mgbe agbazere <200C / elekere.

Jiri mkpọ mgbanaka raara onwe ya nye (zere mmetụta arụrụ arụ).

Q5: Olee otú iji gbochie crucible cracking?

Ejila ihe oyi na-atụ n'ime ọkụ ọkụ (max ΔT <400°C).

Ọnụego jụrụ oyi mgbe agbazere <200C / elekere.

Jiri mkpọ mgbanaka raara onwe ya nye (zere mmetụta arụrụ arụ).

Q6: Gịnị bụ kacha nta iji ibu (MOQ)?

Ụdị ọkọlọtọ: 1 ibe (nlere anya dị).

Nhazi omenala: 10 iberibe (CAD eserese chọrọ).

Q7: Gịnị bụ oge ndu?

⏳Ihe dị n'ahịa: Ụgbọ mmiri n'ime awa 48.

⏳Iwu omenala: 15-25ụbọchịmaka mmepụta na ụbọchị 20 maka ebu.

Q8: Kedu ka esi achọpụta ma ọ bụrụ na crucible adaala?

Mgbawa> 5mm na mgbidi dị n'ime.

Omimi ntinye metal> 2mm.

Nrụrụ> 3% (tụlee mgbanwe dayameta mpụta).

Q9: Ị na-enye nduzi usoro mgbaze?

Igwe ọkụ ọkụ maka ọla dị iche iche.

Ọnụego mgbako ikuku na-adịghị agwụ agwụ.

Nkuzi vidiyo na-ewepu slag.