Efere graphite ahaziri CNC

Atụmatụ

1) Ntugharị ihe: N'ime ụlọ ọrụ na-agbaze, a na-eji efere graphite na-emepụta ihe ndị na-emepụta graphite, dị ka ihe nchebe maka ingots ígwè, na dị ka brik carbon magnesia maka mkpuchi nke ọkụ ọkụ.

2) Ihe na-arụ ọrụ: N'ime ụlọ ọrụ eletriki, a na-ejikarị graphite eme ihe dị ka electrodes, brushes, carbon tubes, na mkpuchi maka tubes telivishọn.

3) Yiri ihe ndị na-eguzogide ọgwụ na mmanu mmanu: N'ọtụtụ ngwa ọrụ, a na-eji efere graphite dị ka ihe na-eguzogide ọgwụ na mmanụ mmanu, nke nwere ike ịfefe na ọsọ 100m / s n'ime oke okpomọkụ nke -200 ruo 2000 ℃ na-enweghị ma ọ bụ jiri obere ojiji nke mmanu mmanu mmanu.

4) Ihe mkpuchi: Jiri graphite na-agbanwe agbanwe dị ka piston mgbanaka gaskets, mgbanaka akara, wdg maka nfuli centrifugal, igwe mmiri mmiri, turbines uzuoku, na akụrụngwa na-ebufe mgbasa ozi corrosive.

5) Ihe na-eguzogide corrosion: Iji graphite efere dị ka arịa, pipeline, na akụrụngwa, ọ nwere ike iguzogide corrosion nke dị iche iche corrosive gas na mmiri mmiri na-eji ọtụtụ ebe na ngalaba dị ka mmanụ ala, chemical, na hydrometallurgy.

6) Ihe mkpuchi okpomọkụ, nguzogide okpomọkụ dị elu, na ihe nchebe radieshon: Enwere ike iji efere graphite mee ihe dị ka neutron moderators na nuklia reactors, nakwa dị ka nozzles, imi cones, aerospace akụrụngwa akụkụ, thermal mkpuchi ihe, radieshon nchedo ihe, wdg.

1. Ezi isotropy, njirimara na-adabere na nha, ọdịdị, na ntụziaka nlele;

2. Ọdịdị n'ụdị, njupụta, na ike antioxidant siri ike;

3. Mma mmanu onwe onye;

4. Ezigbo iguzogide chemical corrosion;

5. High thermal conductivity na arụmọrụ nkwụsi ike;

6. Ike igwe zuru oke na nguzogide mmetụta;

7. Ọ dị mfe iji igwe ma nwee ike ịhazi ya n'ụdị geometric dị iche iche dịka ihe achọrọ.

Mgbe ị na-eji mgbapụta ọhụrụ, ṅaa ntị na ntụziaka nke moto ma zere ijikọ ya ka ọ gbanwee gia.Ntughari ntụgharị ogologo oge nke mgbapụta ga-emebi agụba.

Uzuzu buru ibu na gburugburu ebe nfuli na-arụ ọrụ na nzacha ikuku na-ezughị ezu nwere ike ime ka ike agụba dịkwuo elu ma belata ndụ agụba.

Ebe mmiri mmiri nwere ike ịkpata corrosion na agụba na mgbidi oghere rotor.Mgbe ị na-amalite mgbapụta ikuku, a gaghị atụpụ ihe ndị dị na agụba, n'ihi na nrụgide na-enweghị isi nwere ike imebi agụba.N'ọnọdụ ndị dị otú ahụ, a ga-enyocha agụba ma buru ụzọ hichaa ya.

Ịgbanwegharị ugboro ugboro mgbe ị na-eji mgbapụta na-abawanye ọnụ ọgụgụ nke mmetụta n'oge mkpochapụ agụba, na-ebelata ndụ nke agụba.

Ọdịmma agụba na-adịghị mma nwere ike ime ka arụmọrụ mgbapụta belata ma ọ bụ mebie mgbidi cylinder, yabụ ekwesịrị ịzere ya.

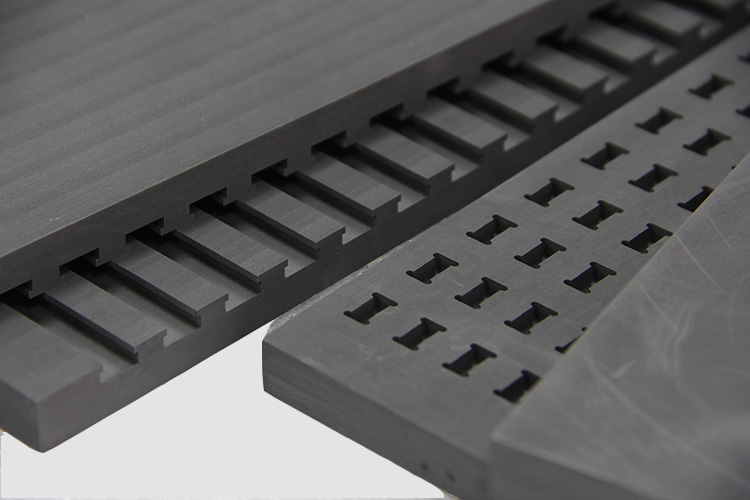

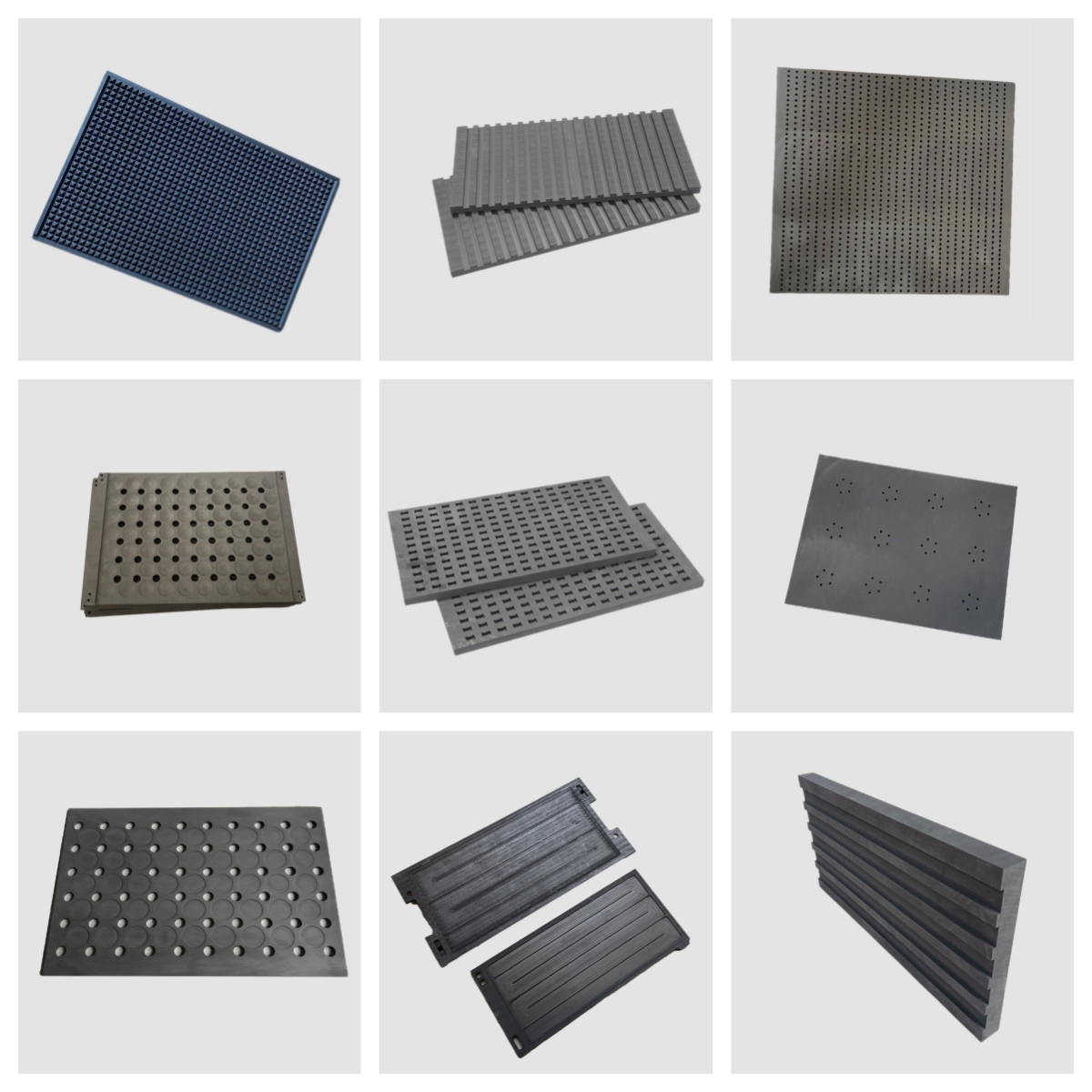

1. Ike nhazi siri ike, nwee ike ịnye nkọwa dị iche iche na efere graphite spliced.

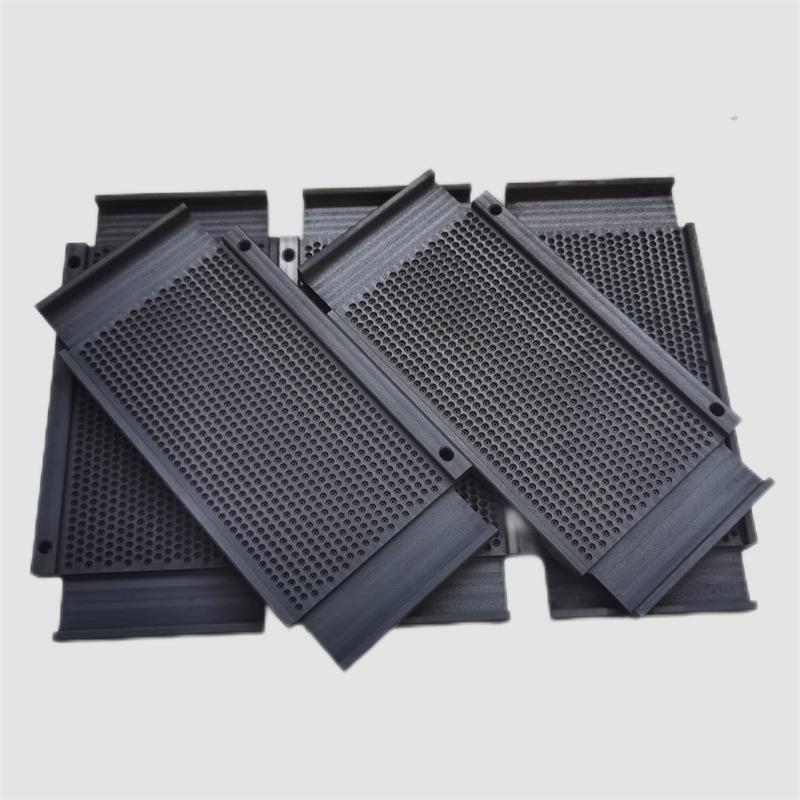

2. Anyị nwere ike na-enye graphite ngwaahịa maka extrusion ịkpụzi, vibration ịkpụzi, ịkpụzi, na isostatic ịpị ịkpụzi dị mkpa.

3. Dị ka teknụzụ dị iche iche chọrọ, ngwaahịa graphite dị ka efere graphite nwere ike idowe ọgwụgwọ nguzogide oxidation, ọgwụgwọ enweghị ike, na ọgwụgwọ nkwado iji melite arụmọrụ ha na ndụ ọrụ.